Systematic • Kinetic • Deliverable

SKD Boiler – Authorized Distributor

Our company strength is in delivery the most efficient manufacturing system for your business. We are the main principle in the country and the region representing producer of the latest and most efficient manufacturing equipments for the food industry.

Standalone Machine (单机)

Our wide range of single unit machine are designed to offer to companies who does not need a fully integrated production system. These machines are individual stand alone catering to one step processing suitable for small to medium capacity production system. Our single production series can also be integrated to an established integrated line production system. Example as addition or replacement unit.

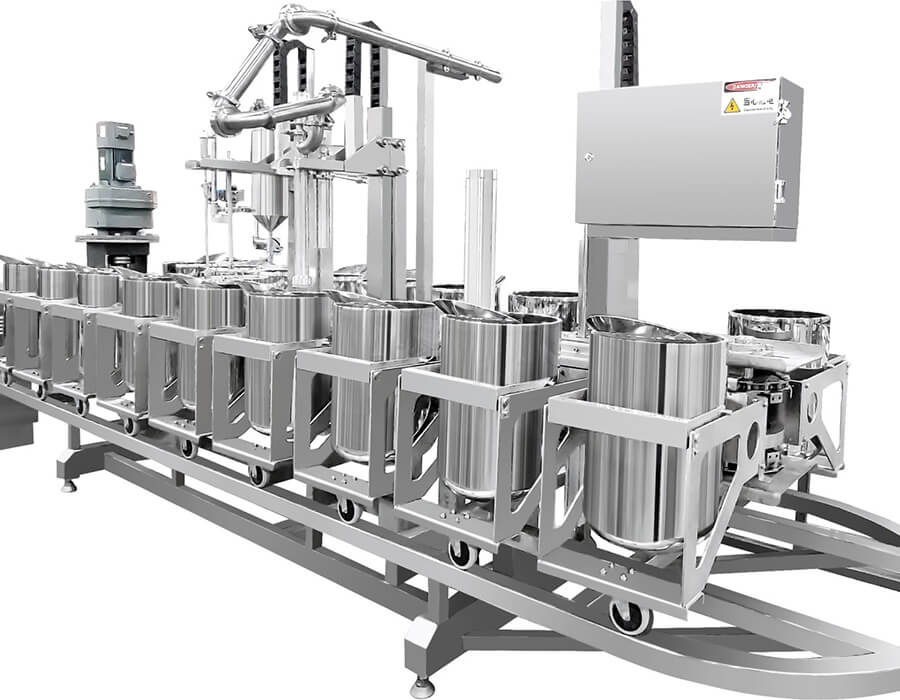

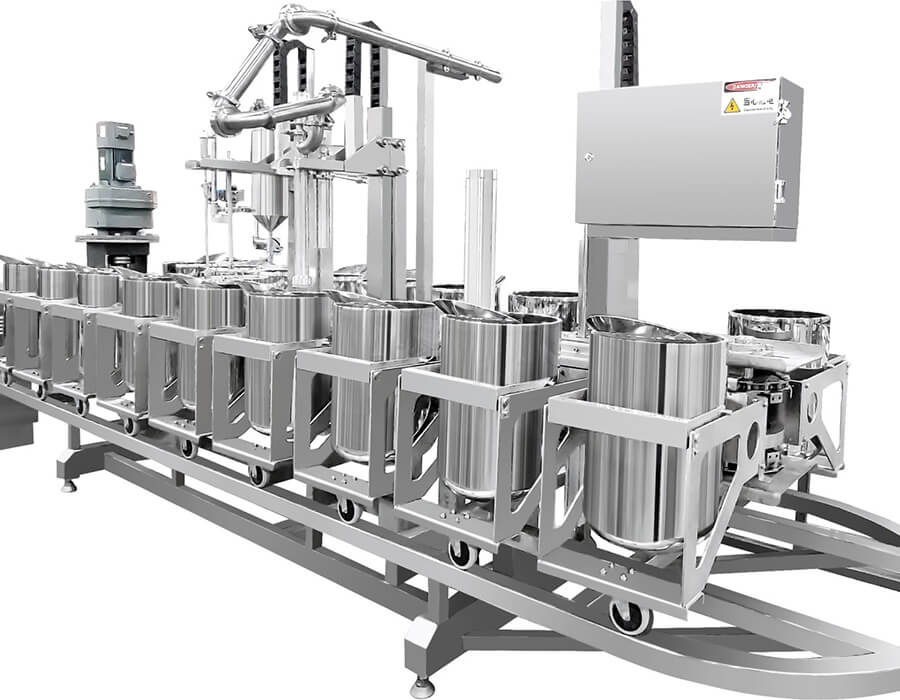

Combination Machine (组机)

Our wide range of fully integrated production unit is available for companies who wishes to automate their production line for fast and cost efficient output. Company can choose the most suitable system based on their requirement based on own decision or working together with our team of experts to decide on the best system for your needs.

Get In Touch With Us

Lorem ipsum dolor sit amet, consectetur adipisicing elit. In minus unde alias eligendi, omnis aut harum incidunt veniam accusamus voluptates, ipsum aliquid libero illo beatae iste, velit quam. Quidem obcaecati quo, eveniet magni quia enim!

浆渣分离系统 Spiral Extrusion Separator Unit

| Specification | |

| 生产能力 Production capacity(大豆 Big Bean) | 100-1200kg/h |

UHT管式超高温灭菌机 UHT Pipe Mode Ultra High Temperature Sterilize

| Specification | |

| 生产能力 Production capacity | 5000-8000KL/h |

点浆凝固系统 Spot Solidification System

自动点浆凝固系统可兼顾不同种类的凝固剂,设计过程考虑了各种凝固剂在豆腐成型中 的不同机理、剂量,可以灵活调整搅拌方式以及凝固时间等参数。在保留、继承传统人 工点浆的各项优点的前提下,实现智能化、自动化、机械化,在提高生产效率的同时, 可以完美提高客户的经济效益。

The automatic pulping and solidification system can take into account different types of coagulants. The design process takes into account the different mechanisms and dosages of various coagulants in tofu molding, and can flexibly adjust parameters such as stirring methods and coagulation time. On the premise of retaining and inheriting the advantages of traditional manual pulping, realizing intelligence, automation and mechanization, while improving production efficiency, it can perfectly improve the economic benefits of customers

设备特点 Features

- 可用于豆干、百页、豆腐等全自动凝固;

- 低位溢流式注浆,减少泡沫,注浆量控制精准;

- 凝固剂与浆充分均匀混合,减少凝固剂使用量,凝固效果佳;

- 无振动运转,蹲脑效果好。

- It can be used for automatic coagulation of dried tofu, hundred pages, tofu, etc.

- The low position overflow type slurry pouring reduces foam and the slurry pouring quantity is precisely controlled.

- The coagulant is sufficiently and evenly mixed with the slurry, and the consumption of coagulant is reduced with good curding effect.

- Operation without vibration, with good standing effect.

| 型号 Model | NGJ-12-LS-101 | NGJ-18-LS-201 |

| 凝固时间 Setting time | 12 – 25 Minutes (Adjustable 可调整) |

12 – 25 Minutes (Adjustable 可调整) |

| 额定电压 Rated voltage | 3N ~ 380V | 3N ~ 380V |

| 额定功率 Rated power | 3.62kW | 3.62kW |

| 外形尺寸 Dimensions | 3600 x 3400 x 3000mm | 5530 x 1320 x 2540mm |

| 型号 Model | NGJ-26-LS-301 | NGJ-32-LS-401 |

| 凝固时间 Setting time | 12 – 25 Minutes (Adjustable 可调整) |

12 – 25 Minutes (Adjustable 可调整) |

| 额定电压 Rated voltage | 3N ~ 380V | 3N ~ 380V |

| 额定功率 Rated power | 3.62kW | 3.62kW |

| 外形尺寸 Dimensions | 7560 x 1320 x 2450mm | 9120 x 1320 x 2450mm |

豆制品综合加工厂生产线车间一角 Comprehensive Bean Product Processing Production Line

| Specification | |

| 生产能力 Production capacity(大豆 Big Bean) | 400-4000kg/h |

卧式生物质蒸汽发生器 Horizontal Biomass Steam Generator

| 型号 Model | FTSG 0.3-0.7-T | FTSG 0.5-0.7-T | FTSG 0.7-0.7-T | FTSG 1.0-0.7-T |

| 额定蒸发量(t/h) Rated Steam Amount |

0.3 | 0.5 | 0.7 | 1 |

| 额定蒸汽温度(°C) Rated Steam Temperature |

170 | |||

| 过热蒸汽温度(°C) Overheat Steam Temperature |

140-260 | |||

| 额定蒸汽气压(Mpa) Rated Steam Pressure |

0.7 | |||

| 热效率 (%) Heat Conductivity |

80-85 | |||

| 生物质燃料耗量(kg/h) Biomass Fuel Consumption |

35-55 | 52-82 | 116-135 | 126-166 |

| 耗电功率(KW) Power Consumption |

5 | 9 | 10 | 12 |

| 运输尺寸(L*W*H) Dimensions |

250*251*270 cm | 260*260*300 cm | 300*270*300 cm | 320*280*300 cm |

| 重量(Kg) Weight |

4500 | 7200 | 8000 | 9000 |

| 适用电源(AC) Suitable Power Supply |

380V 50HZ | |||

| 适用燃料 | 生物质 Biomass | |||

| 燃烧方式 Combusion Method |

微正压燃烧 Micro Pressure Combusion | |||

| 调节方式 Adjustment Method |

自动 Automatic | |||

| 注释: Comments |

1. 以上燃料耗量仅供参考,生物质颗粒4500Kac/h计算 2. 烧生物质需加装生物质燃烧器和生物质情灭底座 |

|||

| 型号 Model | FTSG 1.5-0.7-T | FTSG 2.0-0.7-T | FTSG 3.0-0.09-T |

| 额定蒸发量(t/h) Rated Steam Amount |

1.5 | 2.0 | 3.0 |

| 额定蒸汽温度(°C) Rated Steam Temperature |

170 | ||

| 过热蒸汽温度(°C) Overheat Steam Temperature |

140-260 | ||

| 额定蒸汽气压(Mpa) Rated Steam Pressure |

0.7 | 0.09 | |

| 热效率 (%) Heat Conductivity |

80-85 | ||

| 生物质燃料耗量(kg/h) Biomass Fuel Consumption |

175-223 | 263-350 | 470-500 |

| 耗电功率(KW) Power Consumption |

14 | 15 | 20 |

| 运输尺寸(L*W*H) Dimensions |

410*280*335 cm | 430*300*300 cm | 540*335*340 cm |

| 重量(Kg) Weight |

11000 | 13500 | 17500 |

| 适用电源(AC) Suitable Power Supply |

380V 50HZ | ||

| 适用燃料 | 生物质 Biomass | ||

| 燃烧方式 Combusion Method |

微正压燃烧 Micro Pressure Combusion | ||

| 调节方式 Adjustment Method |

自动 Automatic | ||

| 注释: Comments |

1. 以上燃料耗量仅供参考,生物质颗粒4500Kac/h计算 2. 烧生物质需加装生物质燃烧器和生物质情灭底座 |

||

燃油气生物质两用蒸汽发生器 Dual Use Fuel Biomass Steam Generator

| 型号 Model | LHG 0.3-0.09 | LHG 0.5-0.09 |

| 额定蒸发量(t/h) Rated Steam Amount |

0.3 | 0.5 |

| 额定蒸汽温度(°C) Rated Steam Temperature |

119 | |

| 额定蒸汽气压(Mpa) Rated Steam Pressure |

0.9 | |

| 热效率 (%) Heat Conductivity |

80-93 | |

| 生物质燃料耗量(kg/h) Biomass Fuel Comsumption |

48-62 | 72-98 |

| 额定耗气量(Nm3/h) Rated Air Combusion |

16-22 | 30-36 |

| 运输尺寸(L*W*H) Dimensions |

170*180*210 cm | 180*190*260 cm |

| 适用电源(AC) Suitable Power Supply |

380V 50HZ | |

| 适用燃料 | 生物质/天然气,液化气,柴油 Biomass/natural gas, liquefied gas, diesel |

|

| 燃烧方式 Combusion Method |

微正压燃烧 Micro Pressure Combusion | |

| 调节方式 Adjustment Method |

自动 Automatic | |

| 注释: Comments |

1. 以上燃料耗量仅供参考,生物质颗粒4500Kac/h计算 2. 烧生物质需加装生物质燃烧器和生物质情灭底座 |

|

| 型号 Model | LHG 0.7-0.09 | LHG 1.0-0.09 |

| 额定蒸发量(t/h) Rated Steam Amount |

0.7 | 1 |

| 额定蒸汽温度(°C) Rated Steam Temperature |

119 | |

| 额定蒸汽气压(Mpa) Rated Steam Pressure |

0.9 | |

| 热效率 (%) Heat Conductivity |

80-93 | |

| 生物质燃料耗量(kg/h) Biomass Fuel Comsumption |

118-137 | 165-180 |

| 额定耗气量(Nm3/h) Rated Air Combusion |

42-55 | 59-72 |

| 运输尺寸(L*W*H) Dimensions |

200*210*270 cm | 230*230*270 cm |

| 适用电源(AC) Suitable Power Supply |

380V 50HZ | |

| 适用燃料 | 生物质/天然气,液化气,柴油 Biomass/natural gas, liquefied gas, diesel |

|

| 燃烧方式 Combusion Method |

微正压燃烧 Micro Pressure Combusion | |

| 调节方式 Adjustment Method |

自动 Automatic | |

| 注释: Comments |

1. 以上燃料耗量仅供参考,生物质颗粒4500Kac/h计算 2. 烧生物质需加装生物质燃烧器和生物质情灭底座 |

|

立式生物质蒸汽发生器 Vertical Biomass Steam Generator

| 型号 Model | LHGO 0.3-0.09 | LHGO 0.5-0.09 | LHGO 0.7-0.09 | LHGO 1.0-0.09 |

| 额定蒸发量(t/h) Rated Steam Amount |

0.3 | 0.5 | 0.7 | 1 |

| 额定蒸汽温度(°C) Rated Steam Temperature |

119 | |||

| 额定蒸汽气压(Mpa) Rated Steam Pressure |

0.9 | |||

| 热效率 (%) Heat Conductivity |

80-93 | |||

| 生物质燃料耗量(kg/h) Biomass Fuel Comsumption |

48-62 | 72-98 | 118-137 | 165-180 |

| 重量(T) Weight |

1.5 | 1.8 | 2.4 | 2.9 |

| 运输尺寸(L*W*H) Dimensions |

185*215*260 cm | 200*220*290 cm | 220*240*290 cm | 240*270*292 cm |

| 适用电源(AC) Suitable Power Supply |

380V 50HZ | |||

| 适用燃料 | 生物质 Biomass | |||

| 燃烧方式 Combusion Method |

微正压燃烧 Micro Pressure Combusion | |||

| 调节方式 Adjustment Method |

自动 Automatic | |||

| 注释: Comments |

1. 以上燃料耗量仅供参考,生物质颗粒4500Kac/h计算 2. 烧生物质需加装生物质燃烧器和生物质情灭底座 |

|||

立式燃油气蒸汽发生器 Vertical Fuel Steam Generator

| 型号 Model | LHS 0.2-0.09-YQ | LHS 0.3-0.09-YQ | LHS 0.5-0.09-YQ |

| 额定蒸发量(t/h) Rated Steam Amount |

0.2 | 0.3 | 0.5 |

| 额定蒸汽温度(°C) Rated Steam Temperature |

119 | ||

| 额定蒸汽气压(Mpa) Rated Steam Pressure |

0.9 | ||

| 热效率 (%) Heat Conductivity |

86-93 | ||

| 生物质燃料耗量(kg/h) Biomass Fuel Comsumption |

10-15 | 16-22 | 30-36 |

| 重量(T) Weight |

1 | 1.2 | 1.6 |

| 运输尺寸(L*W*H) Dimensions |

80*80*200 cm | 116*116*210 cm | 130*130*240 cm |

| 适用电源(AC) Suitable Power Supply |

380V 50HZ | ||

| 适用燃料 | 天然气,液化气,柴油 Natural gas, liquefied gas, diesel |

||

| 燃烧方式 Combusion Method |

微正压燃烧 Micro Pressure Combusion | ||

| 调节方式 Adjustment Method |

自动 Automatic | ||

| 注释: Comments |

以上参数按天然气热值8000Kal/m3h计算 | ||

| 型号 Model | LHS 0.7-0.09-YQ | LHS 1.0-0.09-YQ |

| 额定蒸发量(t/h) Rated Steam Amount |

0.7 | 1 |

| 额定蒸汽温度(°C) Rated Steam Temperature |

119 | |

| 额定蒸汽气压(Mpa) Rated Steam Pressure |

0.9 | |

| 热效率 (%) Heat Conductivity |

86-93 | |

| 生物质燃料耗量(kg/h) Biomass Fuel Comsumption |

42-55 | 59-72 |

| 重量(T) Weight |

2.3 | 2.8 |

| 运输尺寸(L*W*H) Dimensions |

150*150*250 cm | 160*160*250 cm |

| 适用电源(AC) Suitable Power Supply |

380V 50HZ | |

| 适用燃料 | 天然气,液化气,柴油 Natural gas, liquefied gas, diesel |

|

| 燃烧方式 Combusion Method |

微正压燃烧 Micro Pressure Combusion | |

| 调节方式 Adjustment Method |

自动 Automatic | |

| 注释: Comments |

以上参数按天然气热值8000Kal/m3h计算 | |

陶瓷磨浆机 Ceramic Refiner

设备特点

Features

- 陶瓷材质膜片,传统石磨方式研黄豆,磨碎颗粒度合理;

- 良好的热传导性,冷磨,热磨均可;

- 磨内配清洗喷头,可CIP清洗。

- Ceramic material grinding disc, grinding system by traditional stone grinding method, the grinding particle size is reasonable;

- Good thermal conductivity, both cold grinding and hot grinding;

- The mill is equipped with a cleaning nozzle, which can be cleaned by CIP.

| 型号 Model | MJJ-150-L-001 | MJJ-205-L-001 |

| 生产能力 Production capacity | 70kg/h(豆) | 200kg/h(豆) |

| 额定电压 Rated voltage | 3N-380V | 3N-380V |

| 额定功率 Rated power | 0.75kW | 3kW |

| 外形尺寸 Dimensions | Φ 0430 x 700mm | Φ 5:40 x 980mm |

| 型号 Model | MJJ-305-LC-001 | MJJ-345-LC-002 |

| 生产能力 Production capacity | 400kg/h(豆) | 600kg/h(豆) |

| 额定电压 Rated voltage | 3N-380V | 3N-380V |

| 额定功率 Rated power | 5.5kW | 11kw |

| 外形尺寸 Dimensions | Φ550 x 1030mm | Φ550 x 1020mm |

螺旋挤压分离机 Spiral Extrusion Separator

设备特点

Features

- 与日本LANDS WORK公司深度合作产品;

- 分离豆渣含水率低至76%;

- 豆浆基本无泡沫产生;

- 可以实现高浓度豆浆的浆渣分离;

- 适用于生浆、熟浆、灭酶磨浆等各种工艺;

- 能耗低、噪音小。

- Low energy consumption and low noise.

- A product produced through in-depth cooperation with Japan LANDS WORK Company

- The moisture rate of separated okara is as low as 76%.

- There is basically no bubble in the soymilk.

- The separation of soymilk and residue for high concentration soymilk can be realized.

- Suitable for various processes as raw soya technology, cooked soya technology, enzyme inactivation grinding process, etc.

- Low energy consumption and low noise.

| 型号 Model | LXJY-6-MI-101 | LXJY-6-MI-33 | LXJY-4-MI-101 |

| 生产能力 Production capacity (干豆Dry Beans) | 600kg/h | 600kg/h | 400kg/h |

| 额定电压 Rated voltage | 3N-280V | 3N-280V | 3N-280V |

| 额定功率 Rated power | 4.05kW | 4.06kW | 2.95kW |

| 外形尺寸 Dimensions | Φ2350 x 1300 x 1800mm | Φ1620 x 1300 x 1780mm | Φ1750 x 1300 x 1800mm |

| 型号 Model | LXJY-3-MI-201 | LXJY-2-MI-101 |

| 生产能力 Production capacity (干豆Dry Beans) | 300kg/h | 200kg/h |

| 额定电压 Rated voltage | 3N-280V | 3N-280V |

| 额定功率 Rated power | 2.4kW | 1.85kW |

| 外形尺寸 Dimensions | Φ1450 x 1300 x 1800mm | Φ1200 x 1300 x 1800mm |

微压煮浆 Micro Pressure Cooking

设备特点

Features

- 程序自动控制汽、浆混合比:

- 菜单式选择煮浆模式;

- 物理方式消泡、无需使用消泡剂;

- 豆浆、豆糊均可煮制:

- 煮制过程中可以排放不良气体;

- CIP 清洗保证食品卫生安全。

- The steam and soymilk mixing ratio is automatically controlled by the program.

- Menu type selection of cooking modes

- Defoaming by physical modes, without the need of using defoamers

- Suitable for cooking soymilk and soybean pastes No bad gas is emitted during the cooking.

- CIP cleaning ensures food sanitation and safety.

| 型号 Model | WYZJ-900-6-101 | WYZJ-750-6-501 | WYZJ-750-5-401 |

| 生产能力 Production capacity | 8T/h | 6T/h | 5T/h |

| 额定电压 Rated voltage | 3N-380V | 3N-380V | 3N-380V |

| 额定功率 Rated power | 6kW | 6kW | 5.25kW |

| 外形尺寸 Dimensions | 6200 x 1600 x 2700mm | 5354 x 1245 x 2083mm | 4530 x 1250 x 2050mm |

| 型号 Model | WYZJ-750-4-301 | WYZJ-750-3-201 |

| 生产能力 Production capacity | 4T/h | 3T/h |

| 额定电压 Rated voltage | 3N-380V | 3N-380V |

| 额定功率 Rated power | 4.5kW | 3.75kW |

| 外形尺寸 Dimensions | 3540 x 1250 x 2050mm | 2750 x 1250 x 2050mm |

制浆集成 (熟浆工艺) Pulping Integration (Cooked Pulp Process)

设备特点

Features

- 用现代工艺技术生产豆制品,豆浆香味醇厚、细腻饱满。

- 全自动控制,无人值守。

- 水豆定分配,豆浆浓度精确控制。

- 可实现生/熟浆工艺切换,满足不同需求。

- Using modern technology to produce traditional soy products, soy milk has a mellow, delicate and full flavor.

- Automatic control, unattended.

- Quantitative distribution of water and beans, precise control of the concentration of soy milk.

- It can realise the switching of raw/cooked pulp process to meet different needs.

| 型号 Model | ZJJC-100-RC-001 |

| 生产能力 Production capacity | 80 – 100kg/h (干豆) |

| 额定电压 Rated voltage | 3N~380V |

| 额定功率 Rated power | 8.97kW |

| 外形尺寸 Dimensions | 2500 x 1200 x 3000mm |